Die Bonding Manufacturer - Top-leading

In back-end semiconductor manufacturing, the die attach process is a critical step. Top-leading’s die attach equipment is based on unique and innovative concepts, offering economic benefits to customers. The Top-leading Die Bonder is a high-precision assembly system engineered for fully automated die attachment in large-scale production environments. Its modular architecture ensures outstanding process reliability, high throughput, and exceptional flexibility.

What is a die bonder? The semiconductor chip manufacturing process is divided into two phases: front-end and back-end. The front-end processing phase involves projecting a circuit pattern onto the surface of a semiconductor wafer so that it is printed onto the wafer, while the back-end processing phase involves dicing the printed wafer into individual chips and assembling them into completed semiconductor devices.

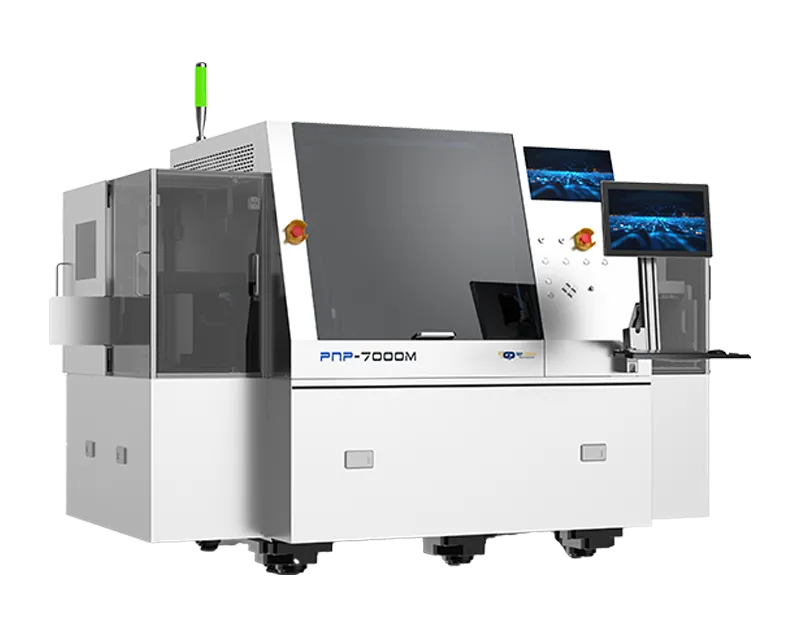

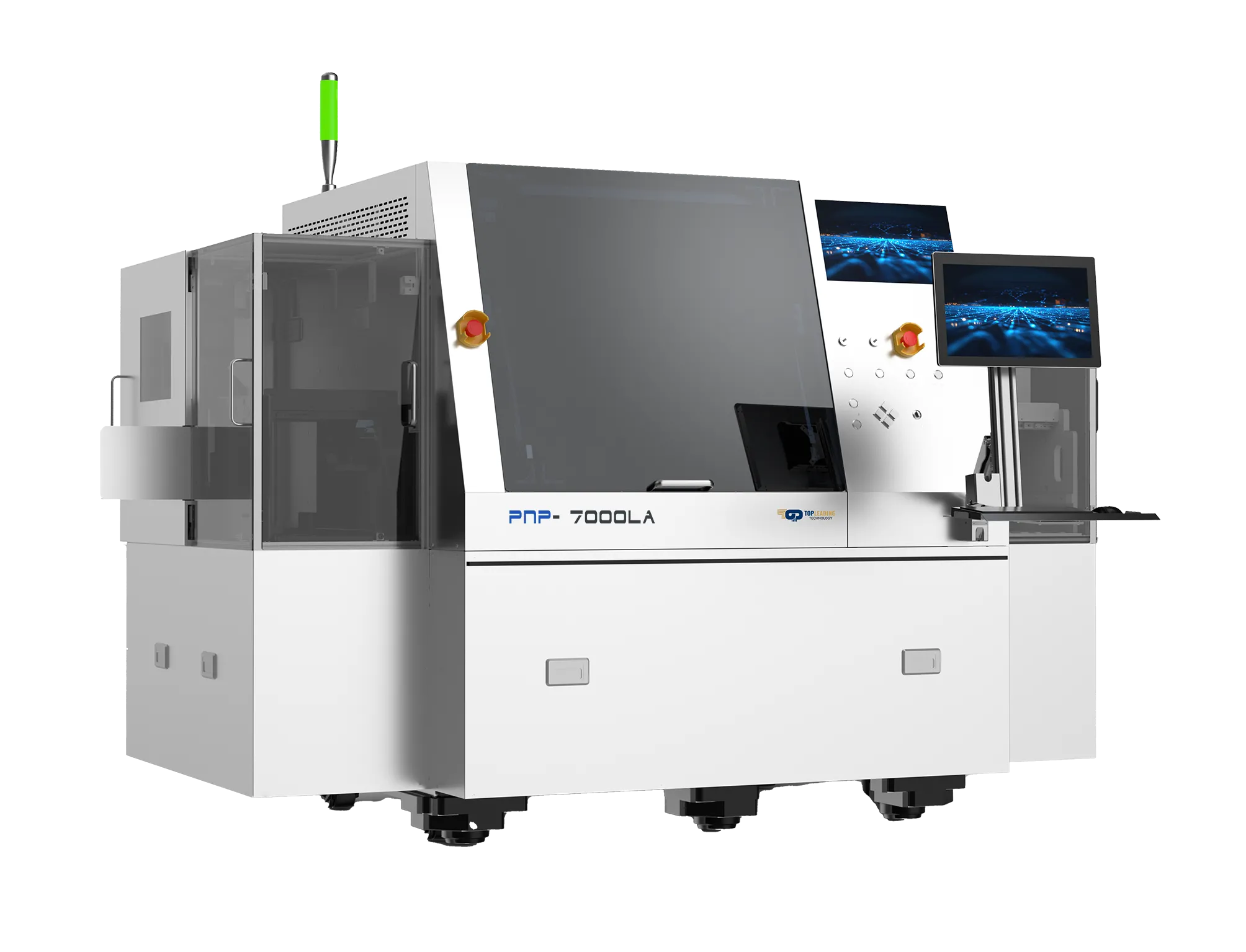

Automatic Die Bonder

Top-leading's automatic die bonder platforms deliver high-precision solutions for semiconductor and microelectronic assembly. Engineered for superior accuracy, unmatched flexibility, and rapid setup, these systems are ideal for a wide range of applications — from research and development and prototyping to high-mix and volume production.

Our die bonders support a broad variety of bonding techniques and component types, making them an excellent choice for advanced packaging and high-precision die attach processes, including:

· Hi-Rel Devices: High-reliability assemblies for aerospace and industrial applications.

· Medical Devices: Precision bonding for embedded or monitoring systems.

· Semiconductor Packaging: Attaching IC dies to packages or substrates.

· Optoelectronics: Assembly of laser diodes, LEDs, and optical modules.

· MEMS & Sensors: Integration of microelectromechanical systems and sensor chips.

· Power Electronics: Bonding high-power dies for automotive and industrial devices.

· RF & Microwave Modules: Assembly of high-frequency components.

Combining micron-level placement accuracy with high-speed operation and exceptional process flexibility, the equipment delivers both precision and performance. Standard features include multi-axis motion control (X, Y, Z, and Theta), vision alignment, and programmable bonding parameters. These capabilities ensure consistent and repeatable results across a wide range of die sizes and materials.

The modular design makes the systems easy to customize. Advanced options such as automatic tool changers, heated workstations, and dispensing units simplify complex bonding tasks. This flexibility allows the equipment to be effectively used in both research and development as well as high-volume production environments.

The range of automatic die bonders, suitable for inline or batch processing, supports various die attach processes, including:

· Epoxy and adhesive bonding

· Eutectic soldering

· Flip chip assembly

· Thermal compression bonding

· Stamping and dispensing techniques

· Standard and custom inspection

Adhesive application technology that creates high-quality semiconductor products

Top-leading’s die bonders not only move semiconductor chips quickly and with high precision, but also use bonding technologies designed to meet diverse customer needs. The type of adhesive used to mount semiconductor chips to the lead frame depends on the customer’s product and varies in viscosity (thickness).

Our die bonders apply the optimal amount, position, and pattern of adhesive for each type to ensure it is evenly spread over the entire surface joining the semiconductor chip and lead frame. This technology helps control temperature rise on the semiconductor chip and prevents the chip from peeling off the lead frame, contributing to the high quality of precision equipment and other semiconductor-based products.

Flexible Die Attach Equipment for R&D and Production

Top-leading’s automatic die bonders are built for versatility, making them suitable for a broad spectrum of applications. The systems handle multiple input formats, including wafer frames, waffle packs, tape & reel, and gel packs. Output formats are almost unlimited, including PCBs, ceramic substrates, lead frames, custom carriers, and devices.

The combination of flexibility, precision, and user-friendly control makes Top-leading’s equipment a powerful solution for today’s advanced die attach requirements.

Get in Touch for Automatic Die Bonding Solutions

Top-leading is your trusted partner for automated die bonding equipment. Whether you’re developing cutting-edge microelectronics or scaling up semiconductor production, Top-leading’s systems deliver the performance and flexibility you need.

If you need help choosing the right die bonding system or have questions about the die attach process, our team of die attach experts is here to help you.